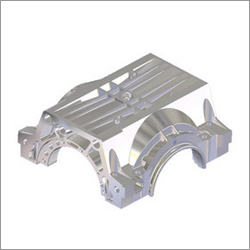

Aluminium Automobile Castings

Price 300-350 INR/ Kilograms

MOQ : 500 Kilograms

Aluminium Automobile Castings Specification

- Product Type

- Automobile Casting

- Casting Process

- Die Casting

- Application

- Automobile Industry

- Method

- Pressure Die Casting

- Surface Treatment

- Polished

- Weight (kg)

- 0.5 - 5

- Color

- Silver Grey

Aluminium Automobile Castings Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 8-10 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- As per the requirement

- Main Domestic Market

- All India

About Aluminium Automobile Castings

We made complex Aluminum Automobile Castings in set time frame and in bulk therefore meeting the end to end requirement of customers efficiently. Our offered product is long lasting, perfect dimension and efficacious, due to which we have received huge appreciation from the customers. This is made possible by our team of experienced professionals having expertise in designing and developing products in accordance with market norms. Our customers can get this Aluminum Automobile Castings from us at market leading rates.

Features:

Features:

- Non-corrosive

- Sturdiness

- Easy to install

- Cost effective

Specification

| Minimum Order Quantity | 1000 Kilogram |

| Material | ALuminium |

| Finishing | Vibro finish |

| Usage/Application | Automobile |

Precision Engineering for Automotive Excellence

Our aluminium automobile castings are designed to meet demanding engineering specifications, delivering reliable strength, lightweight construction, and superior surface smoothness. Each part is custom-manufactured to client drawings, guaranteeing optimal fit and function for automotive assemblies. The pressure die casting process enables high dimensional accuracy and consistent quality for every piece produced.

Dedicated to Quality and Performance

With a focus on quality, our castings feature excellent hardness, corrosion resistance, and a refined polished finish. Each item undergoes rigorous inspection to maintain a tolerance of 0.1 mm, ensuring dependable components that enhance vehicle performance and longevity.

FAQs of Aluminium Automobile Castings:

Q: How are aluminium automobile castings manufactured?

A: Aluminium automobile castings are produced using a pressure die casting process. This method ensures high precision, consistent dimensions, and a smooth, polished surface, meeting the specific requirements provided in customer drawings.Q: What are the benefits of using aluminium alloy castings in automobiles?

A: Aluminium alloy castings offer lightweight strength, enhanced corrosion resistance, and good hardnessall ideal for automotive components. Their low density reduces vehicle weight, improving fuel efficiency and overall performance.Q: Where are these aluminium castings primarily used?

A: These aluminium castings are predominantly used in the automobile industry for manufacturing various automotive parts and components that require precise engineering and durability.Q: What is the standard production capacity for these castings?

A: Our facility is capable of producing up to 5,000 pieces each month, maintaining consistent quality standards for export, manufacturing, and supply.Q: When should I choose custom-shaped aluminium castings for my automotive project?

A: Custom-shaped aluminium castings are ideal when you need parts that match unique design specifications, provide tight tolerances, and enhance the performance or aesthetics of an automotive system.Q: What measures ensure corrosion resistance and finish quality in these castings?

A: These castings undergo a careful surface treatment including polishing, which not only ensures a smooth finish but also improves corrosion resistance, maintaining appearance and functionality over time.Q: How are aluminium automobile castings packaged and shipped from India?

A: Each casting is securely packed in boxes or crates to prevent damage during transit, ensuring safe delivery to domestic and international clients.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Automobile Castings Category

Automotive Castings

Price 300-350 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Automotive Castings

Weight (kg) : 525 Kilograms

Surface Treatment : Polished

Color : Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS