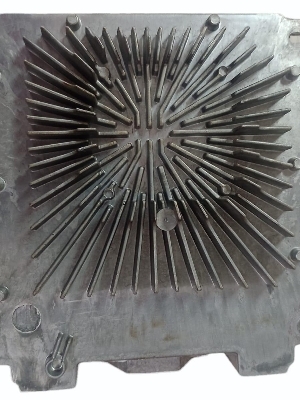

Aluminium Die Casting Components

Price 300-350 INR/ Kilograms

Aluminium Die Casting Components Specification

- Product Type

- Die Cast Aluminium Component

- Casting Process

- High Pressure Die Casting

- Application

- Automobile, Electrical, Machinery Components

- Method

- Die Casting

- Surface Treatment

- Powder Coated / Anodized / Natural

- Weight (kg)

- 0.2 - 5

- Color

- Silver Grey

Aluminium Die Casting Components Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 8-10 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- As per the requirement

- Main Domestic Market

- All India

About Aluminium Die Casting Components

Features:

- Perfect finish

- Long durability

- Non corrosive

- Designed with high accuracy

Precision and Reliability

Engineered with strict tolerances of 0.02 mm and high mechanical strength, our aluminium die casting components offer exceptional reliability for demanding industries. The precision CNC machining process coupled with high-quality aluminium alloy provides both accuracy and longevity, suitable for critical applications in automotive, electrical, and machinery sectors.

Quality Assurance and Standards

Our components conform to international standards, including IS, ASTM, DIN, and JIS, ensuring consistent performance and compatibility. Surface treatments such as powder coating and anodizing further enhance corrosion resistance and aesthetic appeal. Rigorous quality control processes maintain uniformity in each batch produced.

Production and Packaging

With a capacity to manufacture up to 50,000 pieces per month, we efficiently accommodate both large-scale and custom orders. Each component is securely packaged in corrugated boxes or bubble wrap, guaranteeing protection during transport and delivery, whether for domestic or international clients.

FAQs of Aluminium Die Casting Components:

Q: How are aluminium die casting components manufactured?

A: These components are produced using high-pressure die casting, where molten aluminium alloy is injected into customized molds. The process ensures precise dimensions and a smooth finish, followed by CNC machining for further accuracy and specific detailing.Q: What are the benefits of using aluminium alloy for these components?

A: Aluminium alloys provide high mechanical strength, lightweight properties, and excellent corrosion resistance. These attributes result in durable components that perform reliably in automotive, electrical, and machinery applications.Q: What surface treatments are available for these components?

A: Customers can choose from powder coated, anodized, or natural finishes. Each treatment enhances corrosion resistance and surface smoothness, while also offering aesthetic options suitable for various environments.Q: When can I expect my order to be ready for shipment?

A: Production lead times depend on order size and customization requirements, but with a capacity of up to 50,000 pieces per month, typical orders are completed and prepared for dispatch within the stipulated timeline agreed upon at the time of order placement.Q: Where are your aluminium die casting components exported from?

A: Our manufacturing facility is based in India, supplying and exporting components worldwide. We offer secure packaging and reliable logistics to ensure safe delivery regardless of destination.Q: What is the process for OEM supply and custom shapes?

A: We offer OEM services and can manufacture components in custom shapes according to your drawings. Our engineering team reviews your specifications, creates molds, and oversees all stages from die casting to final machining and surface treatment.Q: How are the components packaged to ensure safe delivery?

A: All products are securely packed in corrugated boxes with bubble wrap to prevent damage during transit. This packaging method protects the components from moisture, impact, and abrasion, ensuring they arrive in perfect condition.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Die Castings Category

Aluminium Casting Parts

Price 300-350 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Color : Silver

Casting Process : Die Casting

Method : Pressure Die Casting

Surface Treatment : Other, Powder Coated / Anodized

Housing Body

Price 700 INR / Unit

Minimum Order Quantity : 2000

Color : Silver grey

Casting Process : Die Casting

Method : Pressure Die Casting

Surface Treatment : Casting

CNC Machined Parts

Price 350 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Color : Silver Grey

Casting Process : Other, Not Applicable (Machined from solid metal stock)

Method : CNC Machining

Surface Treatment : Other, Anodizing, Polishing

American Precision Castings

Price 300-350 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Color : Grey

Casting Process : Other, Pressure Die Casting

Method : Casting

Surface Treatment : Other, Powder Coated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS