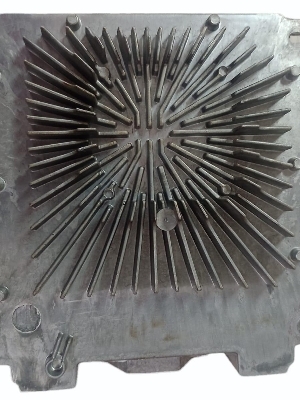

Industrial Aluminium Die Casting

Price 300-350 INR/ Kilograms

Industrial Aluminium Die Casting Specification

- Product Type

- Industrial Aluminium Die Casting

- Casting Process

- Pressure Die Casting

- Application

- Industrial Machinery Parts

- Method

- Die Casting

- Surface Treatment

- Polished

- Weight (kg)

- 1-20

- Color

- Silver

- Finishing

- Smooth

- Lifespan

- Long service life

- Corrosion Resistance

- Yes

- Production Capacity

- According to order

- Material

- Aluminium

- Heat Resistance

- Up to 400°C

- Tolerance

- ±0.1 mm

- Shape

- Custom as per requirement

- Packaging Type

- Wooden box or as required

- Hardness

- Up to 90 HB

- Standards

- ISI, ASTM, DIN

- Dimension

- Customized

Industrial Aluminium Die Casting Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 8-10 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- As per the requirement

- Main Domestic Market

- All India

About Industrial Aluminium Die Casting

Our company has integrated with professional expertise to manufacture, supply and export a foremost range of Die Casting Aluminum. Our offered product is made by a team of experienced professionals by using premium quality aluminum, following the norms and standards laid down by the market. Our Die Casting Aluminum is widely used in tractors, trucks, bikes, and earth moving vehicles. To fulfill the particular requirements of the customers, we provide these castings in different thicknesses and dimensions to opt from.

Features:

- Rugged design

- Light in weight

- Rust proof

- Cost effective

Specification

| Minimum Order Quantity | 1000 Kilogram |

| Material | Aluminium |

| Color | Silver |

Precision and Customization

Our aluminium die casting service excels in delivering parts tailored to your precise requirements. With customizable shapes, dimensions, and tolerances of 0.1 mm, you can be confident each component will satisfy your projects unique needs while maintaining high standards of quality.

Exceptional Durability and Resistance

All castings feature a polished, smooth surface and are engineered for corrosion and heat resistance up to 400C. Combined with a hardness rating of up to 90 HB, these features guarantee that each part will perform reliably and last through challenging industrial use.

Compliant and Versatile Production

Each die-cast part adheres to ISI, ASTM, and DIN standards, ensuring recognized quality and compatibility. Our production capacity is scalable to your order requirements, and secure packaging options like wooden boxes are available to protect your investment during shipping and delivery.

FAQs of Industrial Aluminium Die Casting:

Q: How is the aluminium die casting process carried out for industrial applications?

A: The casting process implements pressure die casting, where molten aluminium is injected into a custom die under high pressure. This method allows for precise shaping, smooth surfaces, and uniform hardness, making it ideal for industrial machinery parts.Q: What are the advantages of using aluminium die cast parts in machinery?

A: Aluminium die cast parts offer significant benefits, including corrosion resistance, heat tolerance up to 400C, high hardness, and a long service life. Their lightweight nature and custom shapes further contribute to operational efficiency and reliability in industrial machines.Q: What surface treatments and finishing options are provided for these castings?

A: Each part receives a polished surface treatment, ensuring a smooth finish. Additionally, the aluminium is inherently corrosion-resistant, enhancing the durability and appearance of the final product in industrial environments.Q: How closely can dimensions and shapes be customized for specific applications?

A: Our process allows for extensive customization of both dimensions and shapes, maintaining tight tolerances of 0.1 mm. This ensures parts precisely fit your machinery requirements and adhere to international standards.Q: Where do you supply and export these aluminium die castings from?

A: We manufacture, supply, and export our aluminium die castings from India, efficiently serving clients domestically and globally.Q: When is it ideal to use pressure die cast aluminium for industrial machinery parts?

A: Pressure die cast aluminium parts are ideal when durability, precision, corrosion resistance, and custom design are critical for the performance and longevity of industrial machinery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Die Castings Category

Housing Body

Price 700 INR / Unit

Minimum Order Quantity : 2000

Method : Pressure Die Casting

Casting Process : Die Casting

Weight (kg) : 1.500 kgs

Surface Treatment : Casting

American Precision Castings

Price 300-350 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Method : Casting

Casting Process : Other, Pressure Die Casting

Weight (kg) : 312 Kilograms (kg)

Surface Treatment : Other, Powder Coated

CNC Machined Parts

Price 350 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Method : CNC Machining

Casting Process : Other, Not Applicable (Machined from solid metal stock)

Weight (kg) : Depends on part geometry (customized)

Surface Treatment : Other, Anodizing, Polishing

Aluminium Casting Components

Price 300-350 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Method : Casting

Casting Process : Other, Die Casting / Sand Casting

Weight (kg) : 0.5 to 5

Surface Treatment : Other, Shot Blasting or Sand Blasted

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS