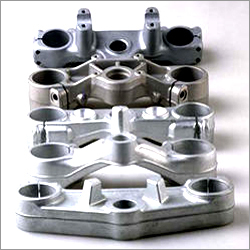

Industrial Aluminum Foundries

Price 50 INR/ Kilograms

MOQ : 500 Kilograms

Industrial Aluminum Foundries Specification

- Color

- Silver Grey

- Product Type

- Aluminum Foundry Casting

- Material

- Aluminum

- Application

- Automobile, Machinery, Electrical, and General Engineering Industries

- Condition

- New

- Power

- Electric

- Voltage

- 220-440 Volt (v)

- Current

- As per requirement

- Use

- Industrial Casting

- Capacity

- Up to 5000 kg per day

- Surface Treatment

- Shot Blasting, Anodizing

- Operating Temperature

- Up to 550°C

- Production Type

- Mass and Batch Production

- Weight

- Custom as required

- Casting Process

- Sand Casting, Die Casting

- Mold Type

- Single and Multi-Cavity Available

- Standards

- ASTM, DIN, ISO Compliant

- Tolerance

- ±0.1 mm

- Finishing

- Smooth, Corrosion Resistant

Industrial Aluminum Foundries Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 20000 Kilograms Per Month

- Delivery Time

- 15-20 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- As per the requirement

- Main Domestic Market

- All India

About Industrial Aluminum Foundries

With the support of our adroit professionals, we have been able to bring forth a high assortment of Aluminum Foundries. Our provided foundries of top notch quality and is offered in different specifications and forms as per to the requirements and prefer of customers. our quality checkers make sure to check this range so as to provide it at customers base without any sort of error. In addition to this, our customers can avail this Aluminum Foundries. at economical rates.

Features:

- Accurate dimensions

- Corrosion free

- Chemical resistant

- Reasonable Cost

Color: silver

Precision Aluminum Casting Solutions

Benefit from advanced sand and die casting methods tailored to industrial standards. Our foundry produces customized aluminum parts with stringent tolerances of 0.1 mm, utilizing single or multi-cavity molds for optimized batch or high-volume needs. Each component meets international quality benchmarks, ensuring reliable performance in demanding environments.

Durable and Corrosion-Resistant Finishes

We deliver aluminum castings with superior surface treatments. Shot blasting ensures a smooth texture, while anodizing boosts corrosion resistance ideal for applications exposed to harsh conditions. Finished parts retain a signature silver grey hue, extending component life and enhancing operational efficiency in your applications.

Trusted Partner for Industrial Applications

Our castings are integral to the automobile, electrical, machinery, and general engineering industries. With production capability reaching 5000 kg per day, we meet bulk requirements efficiently. Embracing global quality standards (ASTM, DIN, ISO), we enable clients worldwide to source dependable components, manufactured in India by skilled professionals.

FAQs of Industrial Aluminum Foundries:

Q: How does your foundry ensure the precise tolerances required for industrial applications?

A: We employ advanced sand and die casting technologies, supported by rigorous quality control and inspection processes. Our ability to achieve tolerances as fine as 0.1 mm is facilitated by precise mold making and modern machinery, ensuring each component meets the exact requirements for industrial use.Q: What surface treatments are available for the aluminum castings, and what benefits do they provide?

A: Our aluminum castings can undergo shot blasting for a smooth, uniform surface, as well as anodizing to enhance corrosion resistance. These treatments improve both the functional durability and appearance of the finished products, making them ideal for challenging operational environments.Q: When should clients consider mass production versus batch production for aluminum castings?

A: Mass production is recommended for large, ongoing orders requiring high volumes of identical components, ensuring cost-effectiveness and consistency. Batch production suits more specific or limited orders, offering flexibility in quantity and design without compromising quality.Q: Where are your aluminum cast components typically used?

A: Our cast components are widely utilized in the automobile, machinery, electrical, and general engineering industries. Their robust construction, corrosion resistance, and dimensional accuracy make them suitable for diverse and demanding industrial applications.Q: What is the typical process for ordering custom aluminum castings from your foundry?

A: Clients can submit their requirements, including designs, weight preferences, and necessary standards. Our team collaborates closely through every stepfrom mold selection (single or multi-cavity) to casting, finishing, and quality verificationdelivering components tailored to client specifications.Q: What standards do your aluminum castings comply with, and why is this important?

A: Our products adhere to international ASTM, DIN, and ISO standards. Compliance ensures every casting is produced with consistent quality, safety, and performance benchmarks, vital for industries requiring high reliability and regulatory adherence.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS