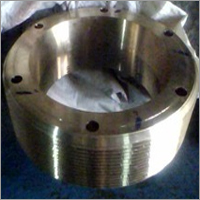

Aluminum Bronze Bush

Price 300-350 INR/ Kilograms

Aluminum Bronze Bush Specification

- Weight

- Depends on Size

- Thickness

- As per Drawing

- Material

- Aluminum Bronze

- Bushes Type

- Sleeve Bush

- Structure

- Solid

- Seals Type

- Without Seals

- Number Of Rows

- Single Row

- Bore Size

- Customizable

- Outside Diameter

- As per Requirement

- Load Capacity

- High Load Bearing

- Inner Diameter

- As per Requirement

- Hardness

- 160-190 HB

- Customization

- Available on Request

- Temperature Resistance

- Up to 400°C

- Standards

- IS, ASTM, DIN Compliant

- Machinability

- Good

- Application

- Automobile, Marine, Pump, and Heavy Machinery

- Shape

- Round

- Elongation

- 15% (Minimum)

- Corrosion Resistance

- Excellent

- Finishing

- Precision Machined

- Tensile Strength

- 600 MPa (Approx.)

Aluminum Bronze Bush Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 15-20 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- As per requirement

- Main Domestic Market

- All India

About Aluminum Bronze Bush

We have a quality range of Aluminum Bronze Bush, which is mainly used in engineering, automotive, and different other industries for make sure tight sealing between two components. We are a reliable manufacturer, supplier and exporter, and therefore, these bushings are manufactured by using premium grade bronze. Our provided Aluminum Bronze Bush are offered in various sizes and dimensions to cater the different requirements of our customers.

Features:

- Corrosion resistant finish

- Rigid structure

- Precise dimensions

- Cost effective

Specification

| Color | silver |

| Surface Finishing | Polished |

| Shape | Circular, Cylindrical, Round, Spherical |

| I Deal In | New Only |

| Product Customization | Yes |

| Material | Bronze |

High Performance and Reliability

Aluminum bronze bushes deliver impressive mechanical properties such as optimal hardness, strength, and elongationensuring long-term reliability and enhanced performance in heavy-duty environments. Their solid sleeve structure and single-row design provide stability and resistance to deformation during operation.

Exceptional Temperature and Corrosion Resistance

With excellent resistance to corrosion and the capability to perform at temperatures as high as 400C, these bushes are particularly suited for challenging conditions in marine, automotive, and industrial applications. Longevity in harsh environments is a key advantage of the aluminum bronze composition.

Precision Machined and Customizable Solutions

Each bush is crafted to customer specifications with high-precision machining, ensuring seamless integration into diverse assemblies. Customization options include bore size, diameter, and thickness, all adhering to strict quality standards, to accommodate a wide array of application needs.

FAQs of Aluminum Bronze Bush:

Q: How are aluminum bronze bushes used in automotive and marine applications?

A: These bushes are commonly employed in automotive and marine systems for their ability to withstand high loads, resist corrosion, and operate effectively at elevated temperatures, ensuring optimal performance and reducing maintenance needs in harsh environments.Q: What is the process for customizing the bore size or dimensions of an aluminum bronze bush?

A: Customization is available on request. Customers can provide their specific requirements, such as inner and outer diameters, length, and thickness, and the bushes will be precision machined accordingly, adhering to IS, ASTM, and DIN standards for quality assurance.Q: When should I select an aluminum bronze sleeve bush over other materials?

A: Aluminum bronze bushes are ideal when applications demand high load capacity, superior corrosion resistance, and the ability to function at temperatures up to 400C, making them suitable for heavy machinery, pumps, and marine installations where durability is crucial.Q: Where are these bushes typically installed within heavy machinery or pump systems?

A: They are installed at rotational or sliding interfaces within pump shafts, gear housings, and bearing assemblies in heavy machinery. Their round, solid, sleeve structure supports optimal alignment and smooth movement under high load conditions.Q: What benefits do precision machined aluminum bronze bushes offer to manufacturers?

A: Manufacturers benefit from consistent dimensions, high surface quality, and ease of installation. Precision machining ensures tight tolerances, reducing friction, wear, and the risk of premature failure in demanding operations.Q: How does the excellent machinability of aluminum bronze impact the manufacturing process?

A: Good machinability allows for efficient shaping, drilling, and finishing, which shortens production times and reduces costs. It also enables intricate customizations and ensures the final product meets exact client specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bronze Bushes Category

Alluminium Rectangular Junction Boxes

Price 300-350 INR / Kiloampere

Minimum Order Quantity : 500 Kilograms

Seals Type : Rubber Gasket Seal

Weight : Approximately 500g 2kg (Depending on size)

Structure : Rectangular

Material : Aluminium

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS