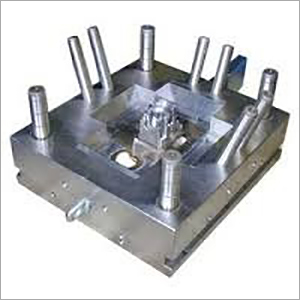

Industrial Pressure Die Casting

Price 300-350 INR/ Kilograms

Industrial Pressure Die Casting Specification

- Material

- Aluminum Alloy

- Tolerance

- 0.01 mm

- Surface Finishing

- Smooth, Polished

- Dimension (L*W*H)

- Customized

- Weight

- 1-5 Kilograms

- Application

- Automotive and Engineering Industries

- Color

- Silver Grey

- Density

- 2.7 g/cm³

- Production Capacity

- Up to 5000 pieces/month

- Corrosion Resistance

- Excellent

- Strength

- High mechanical strength

- Hardness

- 75-85 HB

- Mould Type

- Permanent Steel Mould

- Quality Standard

- ISO 9001:2015 Certified

- Casting Process

- High Pressure Die Casting

- Usage

- Industrial machinery, automotive parts, electrical enclosures

- Shape

- Complex Geometries possible

Industrial Pressure Die Casting Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 8-10 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- As per the requirement

- Main Domestic Market

- All India

About Industrial Pressure Die Casting

We are a professionally involved fast growing company with impressive track record for the manufacturing a complete range of Pressure Die Castings. Our customers can avail from us a wide array of die casting which is manufactured using premium quality materials. Our highly advance Pressure Die Casting is perfectly checked by the quality controllers so as to make sure that our customers must receive flawless range from us and that too at most reasonable prices.

Features:

- Sturdy construction

- Easy to install

- Excellent design

- Cost effective

Specification

| Minimum Order Quantity | 1000 Kilogram |

| Material | Aluminium |

| Size | 500 grams/piece |

Precision High Pressure Die Casting

Utilizing advanced high pressure die casting techniques, our process ensures components with excellent surface finish, tight tolerances, and high repeatability. The use of permanent steel moulds allows for the production of complex shapes and intricate designs, perfectly suited for modern industrial applications.

Superior Materials and Strength

Manufactured from premium aluminum alloys, our die-cast products offer high mechanical strength and excellent corrosion resistance. With a hardness of 75-85 HB and a density of 2.7 g/cm, these components are engineered for durability in rigorous operational environments.

Custom Solutions and Certified Quality

Every casting is tailored to client specifications, including customized dimensions and detailed geometries. Our ISO 9001:2015 certification ensures consistent quality and reliability, supporting both small and large volume orders efficiently.

FAQs of Industrial Pressure Die Casting:

Q: How does high pressure die casting benefit industrial applications?

A: High pressure die casting delivers parts with precise tolerances, complex shapes, and excellent surface finishes. This process is ideal for producing large volumes of consistent, high-strength components required in industrial machinery and automotive engineering.Q: What materials are used in your pressure die casting process?

A: We use premium aluminum alloys in our casting process, chosen for their light weight, high strength, superior corrosion resistance, and suitability for demanding engineering and automotive environments.Q: When should I consider using high pressure die cast components?

A: High pressure die cast parts are recommended when reliability, strength, and dimensional accuracy are critical, particularly for automotive parts, electrical enclosures, or heavy-duty industrial machinery.Q: Where are your pressure die cast products primarily utilized?

A: Our components are widely used in the automotive industry, industrial machinery, and engineering sectors, as well as for specialized applications requiring complex geometries and precise surface finishes.Q: What is the typical production capacity and lead time for your castings?

A: We can produce up to 5,000 pieces per month. Lead times vary based on order size and customization requirements, but our efficient manufacturing ensures timely deliveries for both domestic and international clients.Q: How does your quality assurance process ensure product reliability?

A: Our manufacturing facility is ISO 9001:2015 certified and employs rigorous testing and inspection protocols. Each product is assessed for hardness, dimensional accuracy, surface finish, and material integrity before shipment.Q: What are the main advantages of using aluminum alloy castings in engineering industries?

A: Aluminum alloy castings offer a combination of light weight, high mechanical strength, smooth polished surfaces, excellent corrosion resistance, and versatility in design, making them ideal for advanced engineering applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pressure Die Castings Category

Industrial Aluminium Pressure Die Casting

Price 300-350 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Dimension (L*W*H) : 180 mm x 140 mm x 55 mm

Color : Silver Grey

Application : Industrial Machinery, Automotive Components

Surface Finishing : Other, Smooth, Shot Blasted

Pressure Die Casting

Price 300-350 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Dimension (L*W*H) : Customized as per requirement

Color : Silver

Application : Automotive and Engineering Industries

Surface Finishing : Other, Smooth and Polished

Aluminium Pressure Die Castings

Price 300-350 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Dimension (L*W*H) : As per customer requirements

Color : Silver Grey

Application : Automobile Parts, Electrical Components, Industrial Machinery

Surface Finishing : Other, Smooth, Shot Blasted, Powder Coated

Pressure Die Castings

Price 300-350 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Dimension (L*W*H) : Custom as per requirement

Color : Silvergrey

Application : Automobile and Industrial Components

Surface Finishing : Other, Smooth

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS